Most people have heard of sand blasting and some have heard of shot blasting. Fewer yet have heard of shot peening, but most who have incorrectly assume shot peening is the same thing.

Blasting, whether with shot or sand, is generally used to clean a surface, remove rust, smooth out burrs or change the appearance of a part. Shot peening is used as a surface enhancement process that alters the surface of the object being peened. Just like the blacksmiths of old who would hammer steel to strengthen it, shot peening uses the same method. Media hitting the part induces residual compressive stress, improving resistance to fatigue and stress corrosion cracking.

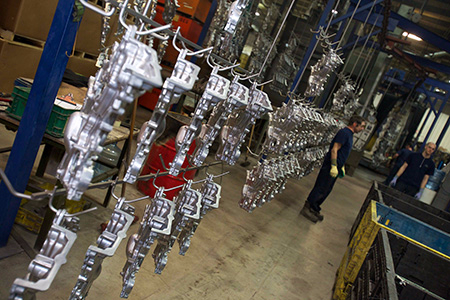

Peening is often used on parts that perform under stress, such as splines, gears and gear shafts.

Properly peening a part includes many factors. Media type, size and hardness is one such factor. Common medias include steel, cut wire, ceramic and glass. Other factors include intensity and coverage. Intensity is the measurement of how hard the media is contacting the surface. This is measured with an Almen strip. Intensity can be affected by distance from the wheel/nozzle to the part, the angle the media is hitting the part, and the speed the peening media is reaching. Coverage is the amount of the surface covered with the shot peen dimples. It can be measured in different ways, but common specifications often ask for 100% coverage or 200% coverage. The type of equipment can also be a factor. Area of peening and/or masking will also need to be addressed.

The peening process is covered by many specifications — the most common one is AMS2430, which replaced Mil-S-13165. Just like a machining process, peening is a measurable, repeatable process that follows exact specifications and procedures. Most OEM shot peen specifications are based on the Mil-S-13165 and AMS2430. This spec will list the type of shot, intensity, coverage and machine.

If you have any questions or requirements for shot peening, feel free to contact us.