Shot peening is a time-tested method of enhancing and strengthening the surface of steel. It is employed as a practical and cost-effective way to extend the lifespan and performance of metal parts in numerous industries.

By introducing residual stress on the surface in a controlled manner, shot peening creates a compressive pressure layer that is more resistant to cracking, fatigue, and oxidation.

How Shot Peening Works

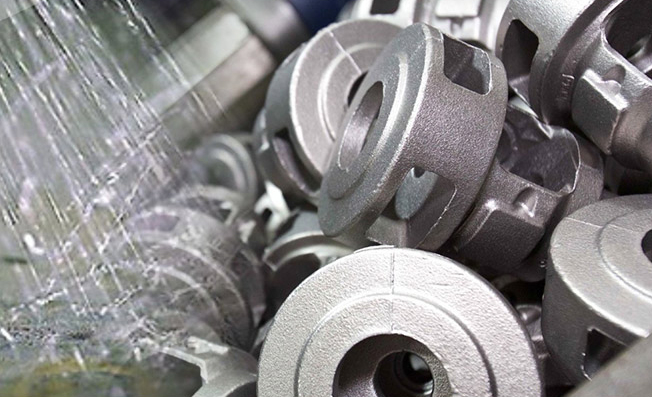

Shot peening entails blasting the part with shot (small beads of metallic, glass or ceramic particles) with sufficient force to create tiny indentations in its surface. Each shot acts as a tiny ball-peen hammer loaded with enough kinetic energy to cause plastic deformation - meaning the metal bends slightly on impact but doesn’t chip or fracture.

When this happens, an area of stress is created on the surface of the part. The material directly beneath the indentation, meanwhile, resists and becomes compressed. Each indentation makes the surface of the material stronger and more resistant to cracking.

This process repeats thousands of times during shot peening, gradually building up a strengthened stress layer that encases the entire component!

Shot peening is typically a cold working or cold forming process, meaning the metal is shaped at room temperature or at least below the recrystallization temperature. Other cold working processes include burnishing, roll forming, embossing and extrusion.

Shot Peening or Shot Blasting?

Shot peening is similar to shot blasting...but differs slightly in process and end result.

Both operate by the mechanism of plasticity, changing the surface of the part while minimizing the amount of material removed in the process. However, shot blasting is most often used to clean and prepare components prior to coating. Shot peening, on the other hand, is used to make components stronger.

How Shot Peening is Applied

Shot peening is used to compensate for tensile stresses that occur during machining. Parts that have been through processes like grinding, milling, bending and heat treatment can often benefit from shot peening.

Compressive surface stresses can protect machined components from numerous performance issues, including:

- Resistance to stress corrosion cracking: Microcracks do not form so readily in materials that are under compressive stress.

- Improved fatigue resistance: Depending on the geometry and material of the part, shot peening and improve fatigue resistance by up to 1000%.

- Improved oxidation resistance of nickel-based alloys: These alloys have wide applications in the aerospace, marine and chemical industries.

Parts that are commonly shot peened include:

- Crankshafts

- Gear wheels

- Connecting rods

- Automotive gear parts

- Coil springs

- Turbine blade

- Airframe components

- Suspension springs

How to Measure Shot Peening Results

Shot peening results are measured using an Almen Strip test.

A flat test strip is placed in the shot chamber to absorb the intensity of the blast, causing it to deform into an arc shape. The height of the arc directly relates to the intensity of the peening blast and the resulting compressive stress.

The intensity (i) of the shot is critical, as overpeening can lead to detrimental effects. Other shot peening parameters include:

- velocity (v) (for wheel machines) or the peening pressure p (for air blast machines)

- peening intensity (see results section)

- mass flow (ṁ)

- coverage

- exposure time (t)

- impingement angle

Our Shot Peening Services

We understand and appreciate that when our customers are faced with a finishing challenge, they look to Latem for an immediate solution.

Contact us to learn more about shot peening and our other metal finishing services.