| Shot blasting with glass or ceramic media is a highly effective surface preparation technique utilized across a spectrum of industries for various applications. This method involves propelling small, spherical beads of glass or ceramic at high velocity onto a surface to achieve desired cleaning, finishing, or texturing effects. This process is integral in tasks ranging from rust removal on metal surfaces to creating matte finishes on delicate materials like glass.

Fundamentals of Shot Blasting: Shot blasting is a mechanical surface treatment method aimed at altering the surface properties of a material. Glass and ceramic media are often preferred choices due to their uniformity in size, shape, and hardness. The process typically involves the following key components: - Media Selection: Glass beads and ceramic beads are the primary media options, each offering distinct characteristics. Glass beads, made from recycled glass, provide a softer, smoother finish suitable for delicate surfaces. On the other hand, ceramic beads, composed of zirconia-alumina-silica, offer enhanced durability and are ideal for tougher materials requiring more aggressive treatment.

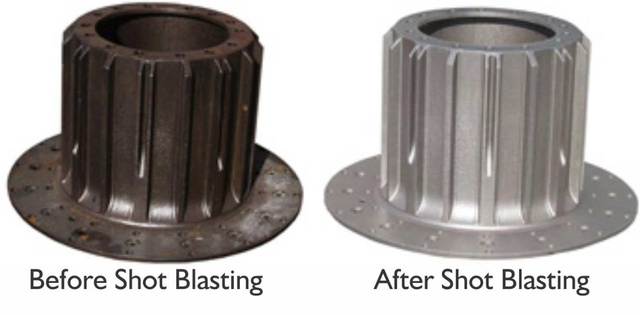

- Surface Preparation: Before shot blasting commences, the target surface undergoes thorough cleaning to remove contaminants such as oil, grease, rust, or existing coatings. This preparatory step ensures optimal adhesion and promotes the effectiveness of the shot blasting process.

- Blasting Process: The chosen media is propelled onto the surface at high velocity using specialized equipment like blast cabinets or blast rooms. Compressed air or centrifugal force propels the beads, causing them to impact the surface, dislodging contaminants, oxides, or unwanted coatings.

Advantages of Glass and Ceramic Media: - Precision: Glass and ceramic media offer precise control over surface finishing. The size and shape uniformity of the beads allow for consistent results, making them suitable for applications requiring high levels of accuracy and repeatability.

- Versatility: These media can be tailored to suit a wide range of materials and surface conditions. Whether it's delicate glassware, hardened steel, or composite materials, shot blasting with glass or ceramic media can effectively address diverse surface treatment requirements.

- Minimal Material Removal: Unlike traditional abrasive blasting methods that rely on sharp-edged particles, glass and ceramic beads exert less aggressive force, resulting in minimal material removal. This characteristic makes them particularly suitable for applications where preserving substrate integrity is crucial.

- Environmental Sustainability: Glass and ceramic media are environmentally friendly options due to their recyclability. After use, the beads can be collected, cleaned, and reused multiple times, minimizing waste generation and promoting sustainable practices.

Applications of Shot Blasting with Glass or Ceramic Media: - Automotive Industry: Shot blasting is commonly employed in the automotive sector for tasks such as paint removal, surface preparation prior to coating application, and refurbishing of engine components. Glass and ceramic media provide an effective means of achieving desired surface finishes without compromising the integrity of automotive parts.

- Aerospace Industry: In aerospace manufacturing, shot blasting plays a crucial role in preparing aircraft components for various processes, including bonding, painting, and corrosion protection. Glass and ceramic media ensure the desired surface cleanliness and roughness required for optimal performance and longevity of aerospace structures.

- Construction Sector: Shot blasting is widely used in construction for cleaning and profiling concrete surfaces, removing surface contaminants, and preparing substrates for waterproofing or coating applications. Glass and ceramic media offer an efficient and environmentally friendly solution for achieving smooth, uniform finishes on concrete surfaces.

- Metalworking and Fabrication: Metalworking industries utilize shot blasting with glass or ceramic media for descaling, deburring, and surface texturing of metal components. Whether it's preparing weld seams or enhancing surface roughness for improved adhesion, these media facilitate precise control over surface properties, leading to enhanced product quality and performance.

In conclusion, shot blasting with glass or ceramic media is a versatile and efficient surface preparation technique with widespread applications across industries. From automotive manufacturing to aerospace engineering and beyond, the use of glass and ceramic beads enables precise control over surface finishes while promoting environmental sustainability through recycling and waste reduction. By leveraging the unique properties of glass and ceramic media, industries can achieve superior surface treatment results while minimizing material waste and environmental impact. Latem Industries Limited offers glass, ceramic and steel shot blasting options. Let our 40+ years of experience work for you. Contact us to find out more. |